Welding ABC

Understanding and preventing common welding defects

15. februar 2024

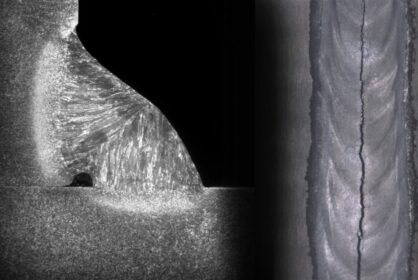

Welding demands precision, but even skilled welders can encounter defects. Understanding common welding issues is critical to ensure high-quality results. Here are some frequent welding defects and how to avoid them.

Susanna Norja

Susanna Norja

Susanna Norja

Editor-in-chief of the Welding Value blog, content producer and Social Media Manager at Kemppi until March 2024.